◎ Overview of the Plan

The Importance of Thermal Management System

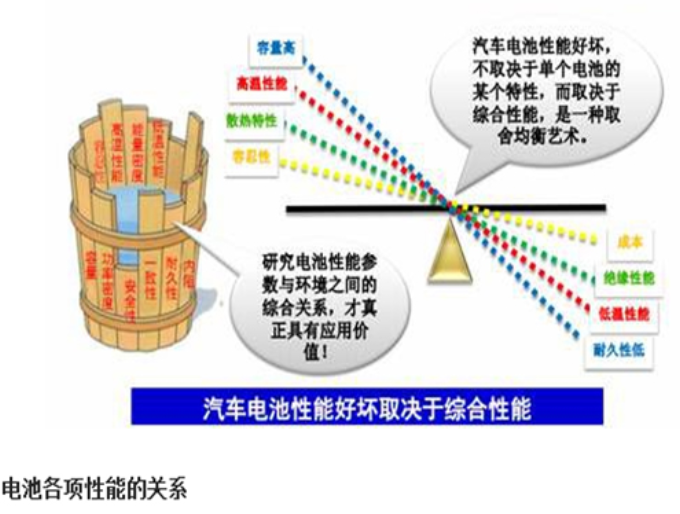

The thermal related issues of batteries are key factors determining their performance, safety, lifespan, and cost of use. Firstly, the temperature level of lithium-ion batteries directly affects their energy and power performance during use. When the temperature is low, the available capacity of the battery will rapidly decay. Charging the battery at too low a temperature (such as below 0 ° C) may cause instantaneous voltage overcharging, leading to internal lithium deposition and subsequent short circuits. Secondly, the thermal related issues of lithium-ion batteries directly affect their safety. Defects in the production and manufacturing process or improper operation during use may cause local overheating of the battery, leading to a chain reaction of heat release and ultimately causing serious thermal runaway events such as smoking, fire, and even explosion, posing a threat to the safety of vehicle drivers and passengers. In addition, the working or storage temperature of lithium-ion batteries affects their service life. The suitable temperature for batteries is between 10-30 ° C, and temperatures that are too high or too low will cause a rapid decline in battery life. The large-scale development of power batteries has led to a relative reduction in the ratio of surface area to volume, making it difficult for the internal heat of the battery to dissipate. This may result in uneven internal temperature and excessive local temperature rise, further accelerating battery degradation, shortening battery life, and increasing the total cost of ownership for users.

The Importance of Thermal Management System

The thermal related issues of batteries are key factors determining their performance, safety, lifespan, and cost of use. Firstly, the temperature level of lithium-ion batteries directly affects their energy and power performance during use. When the temperature is low, the available capacity of the battery will rapidly decay. Charging the battery at too low a temperature (such as below 0 ° C) may cause instantaneous voltage overcharging, leading to internal lithium deposition and subsequent short circuits. Secondly, the thermal related issues of lithium-ion batteries directly affect their safety. Defects in the production and manufacturing process or improper operation during use may cause local overheating of the battery, leading to a chain reaction of heat release and ultimately causing serious thermal runaway events such as smoking, fire, and even explosion, posing a threat to the safety of vehicle drivers and passengers. In addition, the working or storage temperature of lithium-ion batteries affects their service life. The suitable temperature for batteries is between 10-30 ° C, and temperatures that are too high or too low will cause a rapid decline in battery life. The large-scale development of power batteries has led to a relative reduction in the ratio of surface area to volume, making it difficult for the internal heat of the battery to dissipate. This may result in uneven internal temperature and excessive local temperature rise, further accelerating battery degradation, shortening battery life, and increasing the total cost of ownership for users.

The battery thermal management system is one of the key technologies to address the thermal related issues of batteries and ensure the performance, safety, and lifespan of power batteries. The main functions of a thermal management system include: (1) effectively dissipating heat when the battery temperature is high, preventing thermal runaway accidents; (2) Preheat the battery when the temperature is low, increase the battery temperature, and ensure charging and discharging performance and safety at low temperatures; (3) Reduce temperature differences within the battery pack, suppress the formation of local hot zones, prevent rapid degradation of batteries at high temperature locations, and reduce the overall lifespan of the battery pack.

Tesla Roadster The Battery Thermal Management System

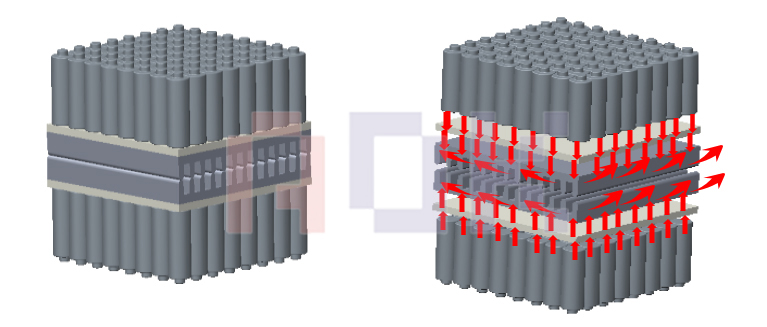

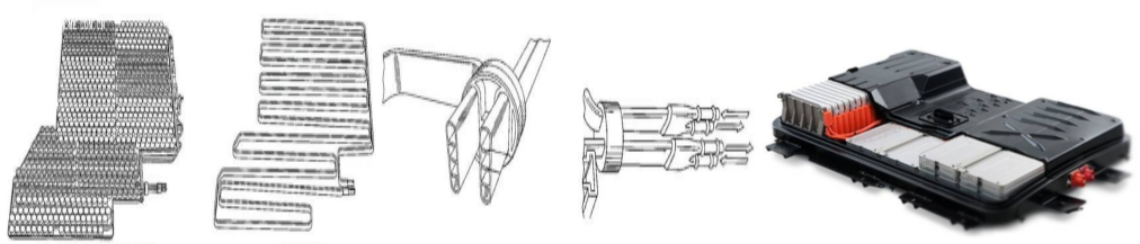

Tesla Motors' Roadster pure electric vehicle adopts a liquid cooled battery thermal management system. The car battery pack consists of 6831 18650 lithium-ion batteries, of which 69 are connected in parallel to form a brick group, 9 groups are connected in series to form a sheet, and finally stacked in series to form 11 layers. The coolant for the battery thermal management system is a mixture of 50% water and 50% ethylene glycol.

Figure 1. (a) shows the thermal management system inside a sheet. The cooling pipeline is arranged in a winding manner between the batteries, and the coolant flows inside the pipeline, taking away the heat generated by the batteries. Figure 1. (b) is a schematic diagram of the structure of the cooling pipeline. The cooling pipeline is divided into four channels inside, as shown in Figure 1 (c). In order to prevent the temperature from gradually increasing during the flow of coolant, which leads to poor heat dissipation at the end, the thermal management system adopts a bidirectional flow field design. The two ends of the cooling pipeline are both inlet and outlet ports, as shown in Figure 1 (d). Fill materials with electrical insulation but good thermal conductivity between batteries and between batteries and pipelines (such as Stycast 2850/ct), which are used to: 1) change the contact form between batteries and heat dissipation pipelines from line contact to surface contact; 2) Beneficial for improving the temperature uniformity between individual cells by one degree; 3) Beneficial for improving the overall heat capacity of the battery pack, thereby reducing the overall average temperature.

Through the above thermal management system, the temperature difference of each individual battery in the Roadster battery pack is controlled within ± 2 ° C. A report in June 2013 showed that after driving 100000 miles, the capacity of the Roadster battery pack could still maintain 80% to 85% of its initial capacity, and the capacity decay was only significantly related to the mileage, and not significantly related to environmental temperature and vehicle age. The achievement of the above results relies on the strong support of the battery thermal management system.

Cooling principle of Tesla battery thermal management system

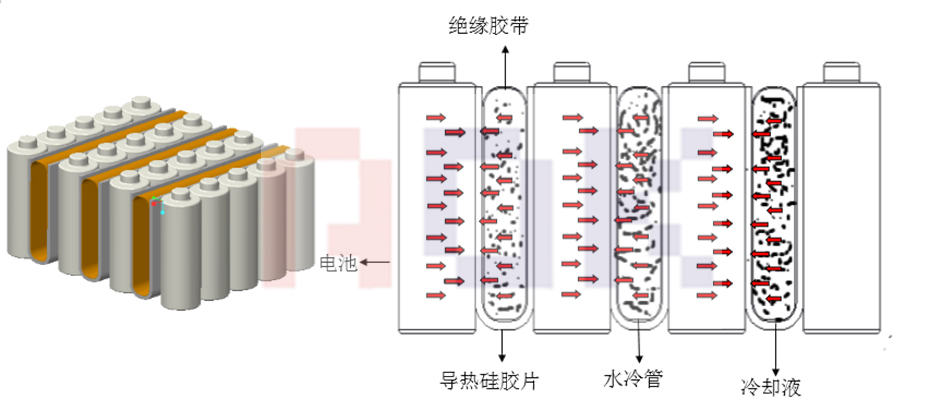

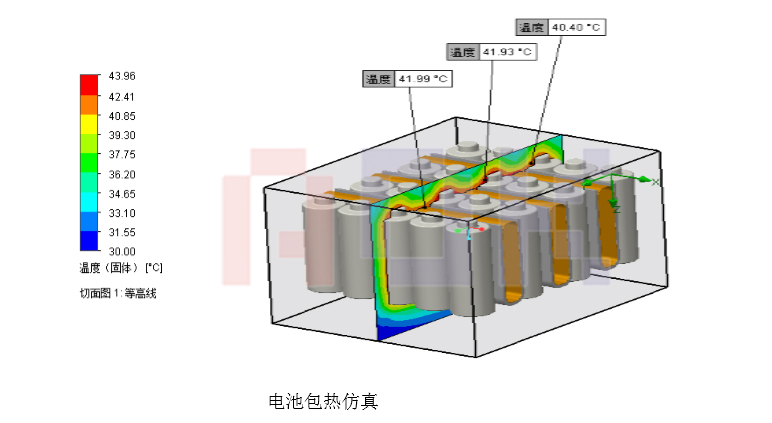

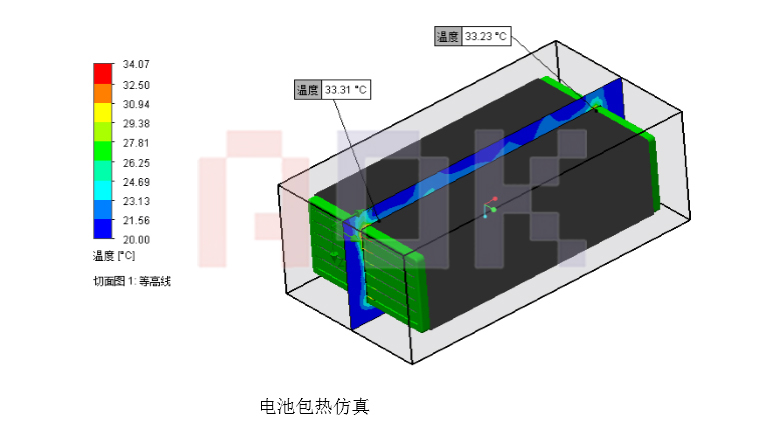

The Sancos thermal solution ensures more stable performance of your car battery, prolongs the lifespan of your battery pack, and maximizes its performance.

Heat dissipation principle: When the battery is working, a large amount of heat is generated, which is transferred to the water-cooled tube by the thermal conductive silicone sheet. The water-cooled tube then transfers the heat to the coolant, and the liquid in the water-cooled tube flows inside the battery pack to remove the heat.

Heat dissipation principle of battery thermal management system of a well-known domestic automobile manufacturer

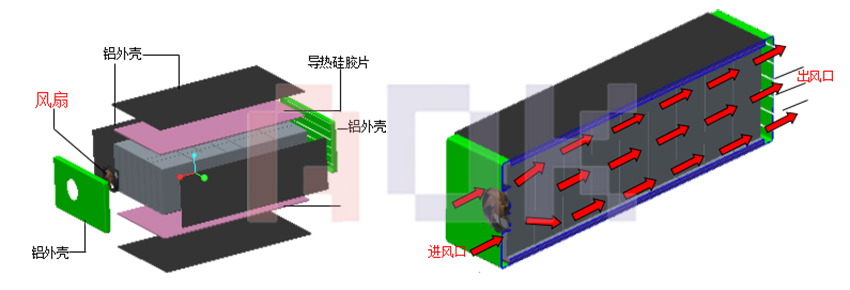

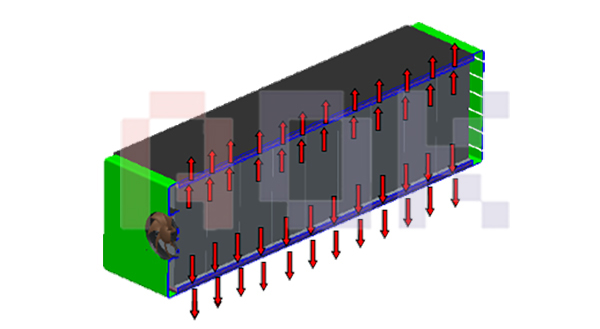

Heat dissipation principle: Utilizing a fan to actively dissipate heat, with the fan supplying air that blows towards the battery channel, removing heat from the inside of the battery pack.

Heat dissipation principle: Due to the temperature difference inside the battery pack not being controlled within 5 ℃, a thermal conductive silicone sheet is attached to both the top and bottom of the battery pack, and the silicone sheet guides the temperature to the outer aluminum shell. The temperature difference of the entire battery module is controlled within 5 ℃, meeting the requirements of the battery pack design, making the battery pack have a longer lifespan and more stable performance during driving.

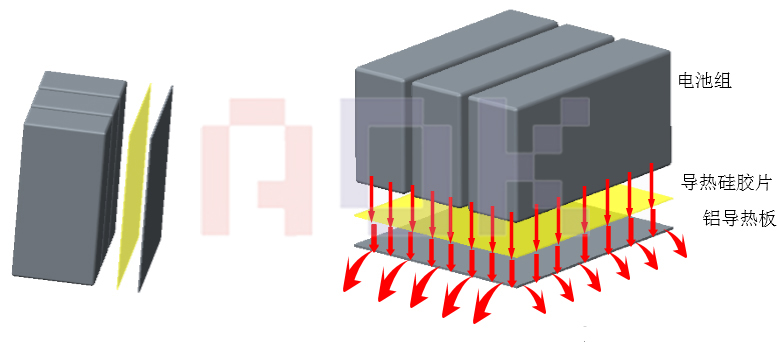

Heat dissipation principle: The battery pack adopts passive heat dissipation. A thermal conductive silicone sheet is attached between the battery pack and the aluminum heat dissipation plate. The silicone sheet transfers the temperature to the aluminum plate, which then exchanges heat with the air

Heat dissipation principle: The battery pack adopts passive heat dissipation. A thermal conductive silicone sheet is attached between the battery pack and the aluminum heat sink. The silicone sheet transfers the temperature to the aluminum heat sink, which then exchanges heat with the air